6000™

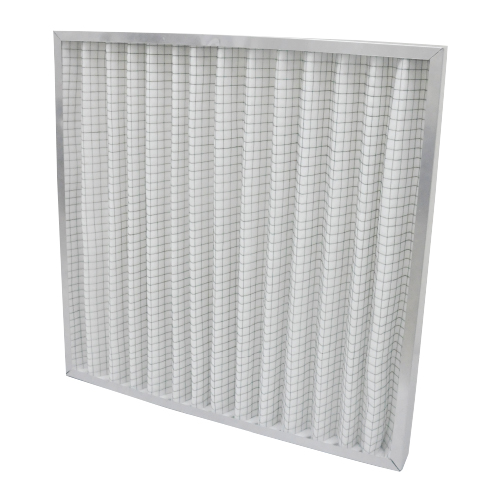

Aluminium Filters

September 23, 2022

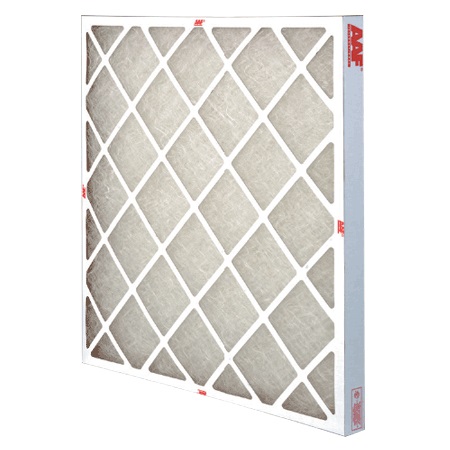

AmAir® 200E / 300E

September 26, 20226000™

Product Overview

- Design for heavy loading conditions

- More dirt-catching media surface area

- Viscosine® adhesive

- Progressive density media construction

- High compression strength

- Environmental friendly

Typical Applications

- Commercial Building

- Schools and Universities

Description

Benefits & Features

Exclusive Media Design Provides Cleaner Air and Longer Service Life

More Media Surface Area

The “6000” filter media contains substantially more glass fibres per square foot than standard filters. More fibres provide greater surface area to catch large quantities of dirt particles. These fibres also significantly reduce the initial resistance.

Progressive Density Media Construction

This unique construction enables “6000” filters to hold more dirt throughout the entire depth of the media. The fibres on the air-entering sides are interlaces with a more open pattern, which becomes progressively tighter towards the air-leaving side. When the media is clean, dirt particles penetrate deeper before being trapped. As the back of the media loads, particles are caught progressively closer to the air-entering surface. This exclusive media design eliminates face loading and increases both arrestance (air cleaning capability) and dust-holding capacity (service life).

Viscosine™ Adhesive

The glass fibres are heavily coated with AAF’s exclusive Viscosine adhesive. The wicking action of the highly viscous adhesive enables it to cling to the fibres and thoroughly saturate each dirt particle. This means accumulated dirt will not break away and blow downstream.

Viscosine adhesive maintains its dirt-trapping characteristic over the life of the filter. It is also non-toxic, flame-retardant, odourless, and completely safe to handle.

High Compression Strength

“6000” filter media is treated with AAF’s specially formulated thermoset resin, which forms a strong bond at each point where fibres intersect, resisting compression in the air stream. As the dirt load builds and resistance increases, the media maintains its thickness without collapsing or face-loading.

Specification

| EN779 | G3 |

| ASHRAE 52.2 | MERV 5 |

| Filter Depth (mm) | 22, 44 |

| Media Type | Fiberglass |

| Frame Material | Moisture Resistant Beverage Board |

| Special Size Available | Yes |

| Antimicrobial Available | No |

| Recomm. Final Resistance | 250 Pa |

| Max. Operating Temperature | 65˚C |

Download

Brochures