MS

NL

June 23, 2022

XS

June 24, 2022MS

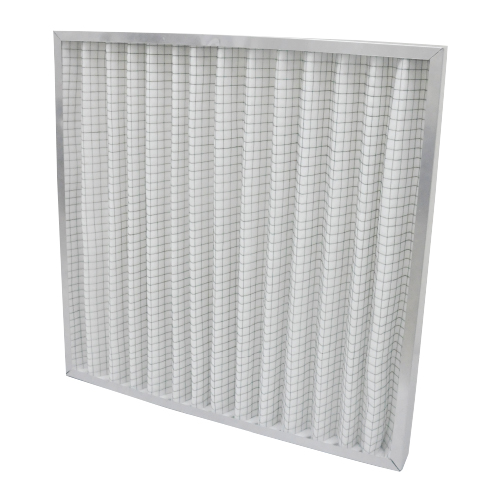

SPLITTER SOUND ATTENUATOR WITH HIGH INSERTION LOSS, EVEN IN THE LOW-FREQUENCY RANGE

Splitter sound attenuator, basically a duct section with integral splitters (type MK) with resonating panels, for ventilation and air conditioning systems

- Attenuation effect due to absorption and resonance

- Energy efficient due to aerodynamically formed frame (bullnose radius 20 mm)

- Sound absorbing material is biosoluble and hence hygienically safe

- Sound absorbing material faced with glass fibre fabric as a protection against erosion due to airflow velocities up to 20 m/s

- The sound absorbing material is non-combustible, to EN 13501, fire rating class A1

- Leakage class C and pressure class 2 according to EN 15727

- For use in areas with potentially explosive atmospheres (according to EC Directive 2014/34/EU (ATEX)), zones 1, 2, and zones 21 and 22 (outside) according to EC Directive 1999/92/EC

- Operating temperature up to 100 °C, with expanded metal (variant L) up to 300 °C for a limited period of time

Optional equipment and accessories

- Expanded metal as an additional mechanical protection for the sound absorbing material

- Stainless steel variant A2 (1.4301), with optional perforated metal facing as an additional protection for the sound absorbing material

- Other stainless steel and aluminium variants as well as PUR coating are upon request

Description

General Information

Application

- Splitter sound attenuators used for the reduction of fan noise and air-regenerated noise in ventilation and air conditioning systems

- Attenuation effect due to absorption and resonance

- Broadband attenuation even in the low frequency range of critical fan noise

- For use in areas with potentially explosive atmospheres (EC Directive 2014/34/EU (ATEX)), zones 1, 2, 21 and 22 (outside) according to Directive 1999/92/EC

Special features

- Resonating panels ensure increased insertion loss in the frequency range of critical fan noise

- Leakage class C and pressure class 2 according to EN 15727

- Energy savings due to aerodynamically formed splitter frame

- Up to 30 % lower differential pressure

- Hygiene tested and compliant with VDI 6022

- Multi-section construction available for large dimensions

Nominal sizes

- Width B: 200, 400, 600, 800, 1000, 1200, 1400, 1600, 1800, 2000, 2200, 2400 mm

- Intermediate sizes: in increments of 1 mm

- Splitter thickness 100 mm: 150 – 2399 mm

- Splitter thickness 200 mm: 250 – 2399 mm

- Splitter thickness 230 mm: 288 – 2399 mm

- Sizes from 2401 – 4800 mm are available with the width subdivided in increments of 1 mm

- Even no. of splitters: centre division

- Odd no. of splitters: off-centre division

- Height H: 300, 400, 500, 600, 700, 800, 900, 1000, 1100, 1200, 1300, 1400, 1500, 1600, 1700, 1800 mm

- Intermediate sizes 150 – 1799 mm in increments of 1 mm

- Sizes from 1801 – 3600 mm are available with the height subdivided in increments of 1 mm

- Centre division

- Length L: 500, 750, 1000, 1250, 1500 mm

- Intermediate sizes 501 – 1499 mm in increments of 1 mm

- Sizes from 1501 – 3000 mm are available with the length subdivided in increments of 1 mm

- Part L1: 1000, 1250, 1500 mm

- Part L2: at least 501 mm and ≤ L1, in increments of 1 mm

- Width and/or height subdivided if B + H > 4200 mm

- Airway width S

- Minimum: splitter thickness T × 0.25, but not < 40 mm

- Maximum: splitter thickness T × 2

- Intermediate sizes: in increments of 1 mm

Variants

- MS with splitter type MK

- Splitter thickness 100 mm

- Splitter thickness 200 mm

- Splitter thickness 230 mm

Construction

- Duct

- No entry: with duct

- OL: without duct (set of MK splitters only)

- Splitter surface

- F: Glass fibre fabric

- L: glass fibre fabric faced with expanded metal as an additional mechanical protection for the sound absorbing material

- Stainless steel construction with perforated metal facing

- Materials and surfaces

- No entry: galvanised steel 1.0917

- A2: stainless steel 1.4301

- P1: splitters powder-coated RAL 7001, silver grey

- Duct connection

- P: flange 30 mm, galvanised or stainless steel

- W: angle section frame 35 × 35 × 3 mm, galvanised

- T: flange 20 mm, galvanised

- Matching frame

- No entry: none

- G: matching frame (only for angle section frame W)

Parts and characteristics

- Duct

- Leakage class C and pressure class 2 according to EN 15727

- Various duct connections available

- Matching frame

- Angle section frame with the same pattern as the requested sound attenuator

- For installation onto a duct (duct by others)

- Aerodynamically formed frame

- Covers the edges of the sound absorbing material

- Reduces the pressure loss

- Helps to optimise the airflow, hence reducing the air-regenerated noise

- Increased rigidity due to special profile

- Absorption material

- Resonating panel

Construction features

- Bent duct with grooves for increased rigidity

- Sound attenuators with angle section frame, width or height subdivided

- Galvanised construction only

- Aerodynamically formed splitter frame (bullnose radius 20 mm) that helps to reduce turbulence on both the upstream and downstream sides; frame with grooves for increased rigidity

- Frame edges with bullnose for increased rigidity

- Operating temperature up to 100 °C; variant L up to 300 °C for 8h max.

Materials and surfaces

- Duct, flange in galvanised sheet steel 1.0917 or stainless steel 1.4301

- Angle section frame in galvanised L steel S235JRC2

- Splitter frame, centre mullion and resonating panels made of galvanised sheet steel 1.0917 or stainless steel 1.4301

- Expanded metal facing made of galvanised steel 1.0917

- Perforated metal facing made of stainless steel 1.4301

- Absorption material is mineral wool

- To EN 13501, fire rating class A1, non-combustible

- RAL quality mark RAL-GZ 388

- Biosoluble and hence hygienically safe according to the German TRGS 905 (Technical Rules for Hazardous Substances) and EU directive 97/69/EC

- Faced with glass fibre fabric as a protection against erosion from airflow velocities of up to 20 m/s

- Inert to fungal and bacterial growth according to EN 846

Standards and guidelines

- Insertion loss and sound power level of air-regenerated noise tested to ISO 7235

- Meets the hygiene requirements of VDI 6022, VDI 3803 Part 1 and DIN 1946 Part 4

- EC Directive 2014/34/EC (ATEX): Equipment and protective systems intended for use in areas with potentially explosive atmospheres

- EC Directive 1999/92/EC (ATEX): Improvement of the safety and health protection of workers potentially at risk from explosive atmospheres

- Leakage class and pressure class according to EN 15727

Maintenance

- Low-maintenance as construction and materials are not subject to wear

- Regular cleaning intervals according to VDI6022

Download

Product Information

Certificates

Operation Manuals