TROX UNIVERSAL

RC

มิถุนายน 29, 2022

EM-TRF

มิถุนายน 29, 2022TROX UNIVERSAL

TROX UNIVERSAL CONTROLLERS FOR THE MOST DEMANDING CONTROL ENGINEERING TASKS

Electronic controller that offers plug and play communication for demanding control tasks, yet simple wiring and commissioning

- Maximum control comfort for clean rooms, hospital wards, and offices

- Demand-based control of supply air, extract air, room pressure and duct pressure

- Interactive configuration software with commissioning wizard, functional testing procedure and Bluetooth adapter

- Perfect system for complete room solutions from a single source

- Plug-in communication cable for easy wiring

- Adaptable control panel and many special functions allow for individual operating modes and control strategies

Expansion options

- Expansion modules with LonWorks, BACnet or Modbus standard interfaces to the central BMS

- Automatic zero point correction for long-term stability and reduced maintenance

- Connection to the mains (230 V)

- Adaptable control panel

คำอธิบาย

Application

Application

- Electronic controller Type TROX UNIVERSAL, for the control of volume flow rate, room pressure or duct pressure, suitable for supply air and extract air and also as an attachment to VAV terminal units

- For use in clean rooms in the pharmaceutical and semiconductor industries, operating theatres, intensive care units, and offices with very demanding control and data transparency requirements

- Fast and stable control of the supply air and extract air flow rates as well as of room pressure and duct pressure

- For extract air led areas such as kitchens

- For supply air led areas such as clean rooms, offices and patient rooms in hospitals

- Options for the integration of additional volume flows into the room balance

- Room pressure and duct pressure control; supply air or extract air flow rate measurement as an option (expansion module)

- Features

- Controllers can be used individually or combined with other controllers for a complete room solution

- System solution for the volume flow control in rooms (room balance)

- Central BMS interface, 0 – 10 V voltage signals, digital inputs and outputs, expansion modules for LonWorks, BACnet, Modbus

Special characteristics

- Plug and play communication system with automatic controller identification, no component addressing required

- Modular system for functional expansion

- Connections and status displays on the outside of the controller casing

- Project-specific adjustments with adaptable room control panel

- Project-specific adjustments can be achieved with configurable special functions, monitoring, and alarm signalling

- Permanent function monitoring of the system and the connected sensors

- Very simple commissioning with software wizard for configuration changes, maintenance and diagnosis

- Centralised configuring and permanent signalling of room settings (room management function)

- EasyConnect configuration software enables interactive navigation (with optional BlueCon adapter, wireless controller configuration)

- Factory tested and configured with projectspecific parameters

Description

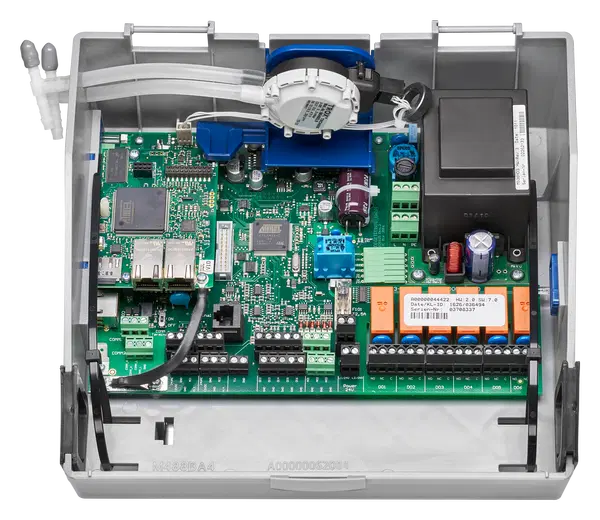

Parts and characteristics

- Ready-to-commission controller, as an attachment for air terminal units

- Static differential pressure transducer for rapid actual value measurement

- Microprocessor system with programme and system data stored in nonvolatile memory

- Double-stack terminal block for supply voltage connection

- Connections for two control panels

- Connection of communication cable to plug socket or screw terminals

- Digital inputs with screw terminals or plug socket

- Analogue inputs with screw terminals or plug socket

- Analogue outputs with screw terminals or plug socket (actuator)

- Control input signal for various actuators: standard actuator with 150 s running time, actuator with 150 s running time and safe position (spring return), fast-running 3 s actuator; all actuators for 90° damper blade position

- Integral terminal resistor for the communication cable

- Alarm indicator lights on both sides of the casing

- Status indicator lights (heartbeat, communication and terminal resistor)

Attachments

Expansion modules are factory mounted or can be fitted at a later stage

- T: EM-TRF, power supply unit for connecting the controller to the 230 V AC mains voltage

- U: EM-TRF-USV, power supply unit for connecting the controller to the 230 V AC mains voltage, including uninterruptible power supply (with battery backup, 4 h), volume flow rate measurement for room and duct pressure controllers

- Z: EM-AUTOZERO, automatic zero point correction for long-term stable volume flow rate measurement and hence reduced maintenance.

- L: EM-LON, LonWorks FTT-10A interface

- B: EM-BAC-MOD-01, interface for BACnet MS/TP

- M: EM-BAC-MOD-01, interface for Modbus RTU

- I: EM-IP, BACnet-IP, Modbus-IP, web server interface

- R: EM-IP, BACnet-IP, Modbus-IP, web server interface with real time clock

Useful additions

- BE-LCD: Room control panel

- Static differential pressure transducer for room pressure control

- Static differential pressure transducer for duct pressure control, including tube and pressure tap

- EasyConnect: Configuration software for the commissioning and diagnosis of TROX UNIVERSAL and EASYLAB systems; BlueCon Bluetooth adapter module available as an option

- EasyCon Android app for maintenance and diagnosis as well as for reading and writing certain parameters (only with TROX BlueCon adapter module)

Construction features

- Control unit complete with all expansion modules in a plastic casing and attached to the air terminal unit

- Controller casing can be opened without tools, except for controllers with with EM-TRF or EMTRF- USV

- Expansion modules can be easily retrofitted (automatic recognition, plug and play)

- Pin header socket for the connection of expansion modules

- Plug sockets for the most important connections on the outside of the casing

- Static differential pressure transducer with room air induction to protect the sensor

Materials and surfaces

- Casing made of ABS plastic, UL94, V0, lower part in grey (RAL 7037), with blue cover (RAL 5002)

Maintenance

- Zero point correction of the static differential pressure transducer should be carried out once per year (recommendation)

- If you use expansion module EM-AUTOZERO for automatic zero point correction, no manual correction is required

Download

Product Information

Certificates

Operation Manuals

Software