MK

RK

มิถุนายน 24, 2022

TS

มิถุนายน 24, 2022MK

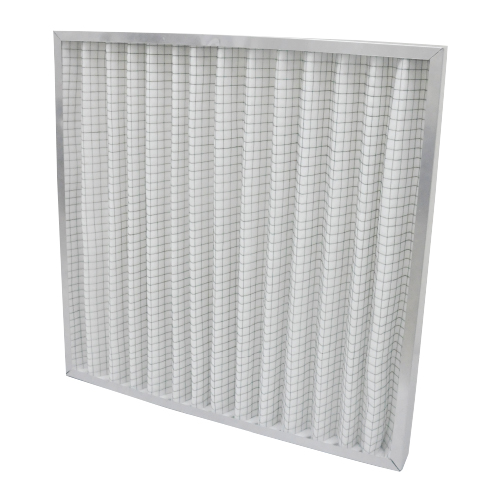

SPLITTER WITH HIGH INSERTION LOSS AND BROADBAND ATTENUATION EVEN IN THE LOW FREQUENCY RANGE

Sound attenuator splitters with resonating panels, ready to be used in ventilation and air conditioning systems

- Attenuation effect due to absorption and resonance

- Energy efficient due to aerodynamically formed frame (bullnose radius 20 mm)

- Acoustic data measured to EN ISO 7235

- Sound absorbing material is biosoluble and hence hygienically safe

- Sound absorbing material faced with glass fibre fabric as a protection against erosion due to airflow velocities up to 20 m/s

- The sound absorbing material is non-combustible, to EN 13501, fire rating class A1

- For use in areas with potentially explosive atmospheres (according to EC Directive 2014/34/EU (ATEX)), zones 1, 2, and zones 21 and 22 (outside) according to EC Directive 1999/92/EC

- Operating temperature up to 100 °C, with expanded metal (variant L) up to 300 °C for a limited period of time

Optional equipment and accessories

- Expanded metal as an additional mechanical protection for the sound absorbing material

- Stainless steel variant A2 (1.4301), with optional perforated metal facing as an additional protection for the sound absorbing material

- Other stainless steel and aluminium variants as well as PUR coating are upon request

- Fitting accessories to join subdivided attenuator splitters

คำอธิบาย

General Information

Application

- Sound attenuator splitters with resonating panels are used for the reduction of fan and air-regenerated noise in ventilation and air conditioning systems

- Attenuation effect due to absorption and resonance

- Broadband attenuation even in the low frequency range of critical fan noise

- Hygiene tested and compliant with VDI 6022

- For use in areas with potentially explosive atmospheres (EC Directive 2014/34/EU (ATEX)), zones 1, 2, 21 and 22 (outside) according to Directive 1999/92/EC

Special features

Resonating panels ensure increased insertion loss in the frequency range of critical fan noise

- Energy savings due to aerodynamically formed splitter frame

- Up to 30 % lower differential pressure

- Hygiene tested and compliant with VDI 6022

- Multi-section construction available for large dimensions

Nominal sizes

- H: 150 – 2500 mm

- L: 500, 750, 1000, 1250, 1500, 1750, 2000, 2250, 2500 mm

- Intermediate sizes of H and L are possible: 150 – 2500 mm in increments of 1 mm

- Undivided construction: H + L 600 mm min., 4000 mm max., 100 kg max.

- Size limit for H or L: If one dimension is greater than 1500 mm, the other one must not exceed 1500 mm

- Height and length subdivided in case of deviation, or a dimension 2501 – 5000 mm

- Height subdivided from H ≥ 2501 mm, otherwise length subdivided

Variants

- MK100: splitter thickness 100 mm

- MK200: splitter thickness 200 mm

- MK230: splitter thickness 230 mm

Construction

Half of the splitter is covered by a resonating panel

- F: Glass fibre fabric

- L: glass fibre fabric faced with expanded metal as an additional mechanical protection for the sound absorbing material

Materials and surfaces

- No entry: Galvanised steel 1.0917

- A2: Stainless steel 1.4301

- Construction L: Glass fibre fabric with perforated metal facing as an additional mechanical protection for the sound absorbing material

- P1: Powder-coated RAL 7001, silver grey

Parts and characteristics

- Aerodynamically profiled frame

- Reduced weight and increased rigidity due to special profile

- Helps to optimise the airflow, hence reducing the air-regenerated noise

- Reduces the pressure loss

- Covers the edges of the sound absorbing material

- Absorption material and resonating panels fitted to reduce air-regenerated noise by absorption and resonance

Accessories

- U-sheets/clamp sheets to join subdivided attenuator splitters (included with subdivided splitter constructions)

Construction features

- Aerodynamically formed splitter frame (bullnose radius 20 mm) that helps to reduce turbulence on both the upstream and downstream sides; frame with grooves for increased rigidity

- Frame edges with bullnose to protect the infill

- Operating temperature up to 100 °C; variant L up to 300 °C for 8h max.

Materials and surfaces

- Splitter frames, centre mullion and resonating panels made of galvanised sheet steel 1.0917 or stainless steel 1.4301

- Expanded metal facing made of galvanised steel 1.0917

- Perforated metal facing made of stainless steel 1.4301

- Absorption material is mineral wool

- To EN 13501, fire rating Class A1, non-combustible

- RAL quality mark RAL-GZ 388

- Biosoluble and hence non-hazardous to health according to the German TRGS 905 (Technical Rules for Hazardous Substances) and EU Directive 97/69/EC

- Faced with glass fibre fabric as a protection against erosion from airflow velocities of up to 20 m/s

- Inert to fungal and bacterial growth according to EN 846

Standards and guidelines

- Insertion loss and sound power level of air-regenerated noise tested to ISO 7235

- Meets the hygiene requirements of VDI 6022, VDI 3803 Part 1 and DIN 1946 Part 4

- EC Directive 2014/34/EC (ATEX): Equipment and protective systems intended for use in areas with potentially explosive atmospheres

- EC Directive 1999/92/EC (ATEX): Improvement of the safety and health protection of workers potentially at risk from explosive atmospheres.

Maintenance

- Low-maintenance as construction and materials are not subject to wear

Download

Product Information

Certificates

Operation Manuals